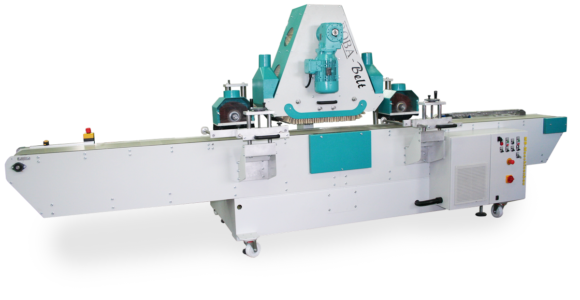

The brush sanding system ROBA Belt is a unique development of MB in the field of metal working.

Due to the modular design of the machine line the customer has the chance to choose between various combinations of different units coming out of MB Maschinenbau program. In this way parts can be machined in a through feed process for high volumes or, for complex part geometries, placed on customized jig transport systems.

Below are some examples of customer requirements that MB has realized in the past.

Task 1: deburring of cabriolet top hinges for a German automotive supplier

The aim was to deburr the three-dimensionally shaped cabriolet top hinges and to give the surface a finish. Since the painting of the parts consists of an extremely thin coating, the surface quality has to be exceptionally good.

The machining of the parts is integrated in a welding robot cell and therefore the machines capacity has to be adapted to this number of cycles.

To accomplish this task MB used its proven ROBA Belt series and added two finishing brushes. Additionally a magazine transport system had been developed that was capable of receiving five hinges simultaneously.

The hinges are placed in the magazine, transported through the machine to be processed, reversed to come back to operator at the end of the cycle. An automatic mode ensures that the machine sets up all the necessary sanding units for the forward or backward process accordingly. As the hinges pass through the ROBA Belt, the operator is able to charge the welding robot with the previous batch.

Task 2: deburring and finishing of floor drains for showers

The aim was to deburr stainless steel floor drains for showers in many variations and to give them a defined hair line image. Due to the deep drawing production process the parts are not plain in the top area and as a whole a bit twisted. That’s why only a brush system could be used.

Therefore MB decided to use its proven ROBA Belt series and added to the machine finishing units. For the part transport it was necessary to develop a cam transport, since the reference point to clamp the work piece is situated in a fold. In order to achieve a long life span of the tools, MB built in a long-stroke oscillation, which allows using the entire 300mm processing width of the ROBA Belt series.

The oscillation of the finishing units is overlapped with a short stroke movement which positively affects the image of the hair lines of the stainless steel parts.

Task 3: deburring and finishing of machined aluminum profiles

The aim was to deburr aluminum profiles of a packaging machine manufacturer and to polish the surface on the whole and in the corner areas of the milled grooves. This is necessary to avoid the super thin packaging films, which slide through these grooves, to stop or jam. Due to the high speed part flow of the transport operation an absolute reliable process has to be guaranteed.

Since the aluminum profiles are available in short and long measurements, the customer can opt for a continuous process, or decide to get the parts back to the operator by reversing the transport system.

Have a question about our products?

Do you want a detailed consultation or an offer?

Then call us now or send us an inquiry using the form below that we are able to contact you.