MB Maschinenbau designs, develops and distributes sanding and special machinery for the wood and metal industry. With over 25 years of experience and a knowledgable team of specialists, MB is a main player in the industry when it comes to highest requirements.

We invite you to visit our sanding laboratory in Herford. Or visit us at one of our international fairs.

The trade fair highlight in May 2025:

• Ligna 2025

• The new event takes place from 26.-30. May 2025 and offers interested customers the opportunity to see latest MB innovations.

• For more information visit: Ligna

Ligna 2025 trade fair highlight: ROBA Orbital sander

Innovative orbital sanding

The furniture business also thrives on innovations that produce attractive furniture designs and new surfaces or optimize production processes to counter the high-cost pressure.

The new ROBA Orbital development in the field of sanding cabinet doors, which caused a sensation at the recently concluded IWF in Atlanta, tackles all these requirements in a multi-layered way.

The ROBA Orbital is designed for customers who, on the one hand, want to provide perfect foil or lacquered surfaces for flat workpieces with a high-quality sanding, or who produce furniture fronts in shaker design with a deeper filling made of MDF or solid wood.

If these fronts are made of MDF and the filling is created by clearing the center panel by using a CNC router, many milling lines are created. These overlaps of the tool paths must always be completely eliminated, otherwise they will holograph through a PVC film or paint layer.

Wood based cabinet doors have a different challenge: veneered fillings, raw or lacquered, must always be sanded smooth to ensure a top surface. In the case of framed doors, the sanding marks on the cross rials created by the widebelt sander must be removed.

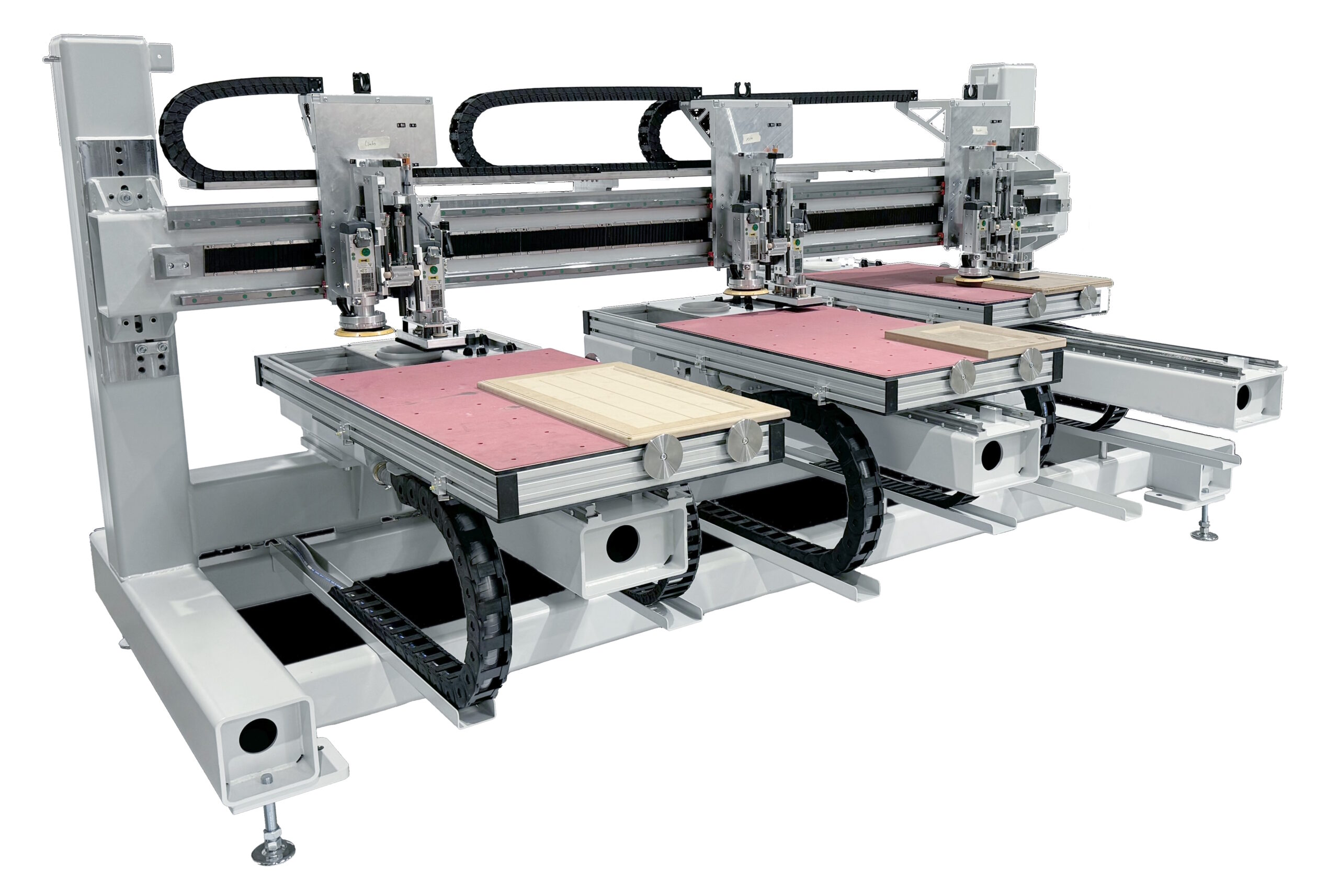

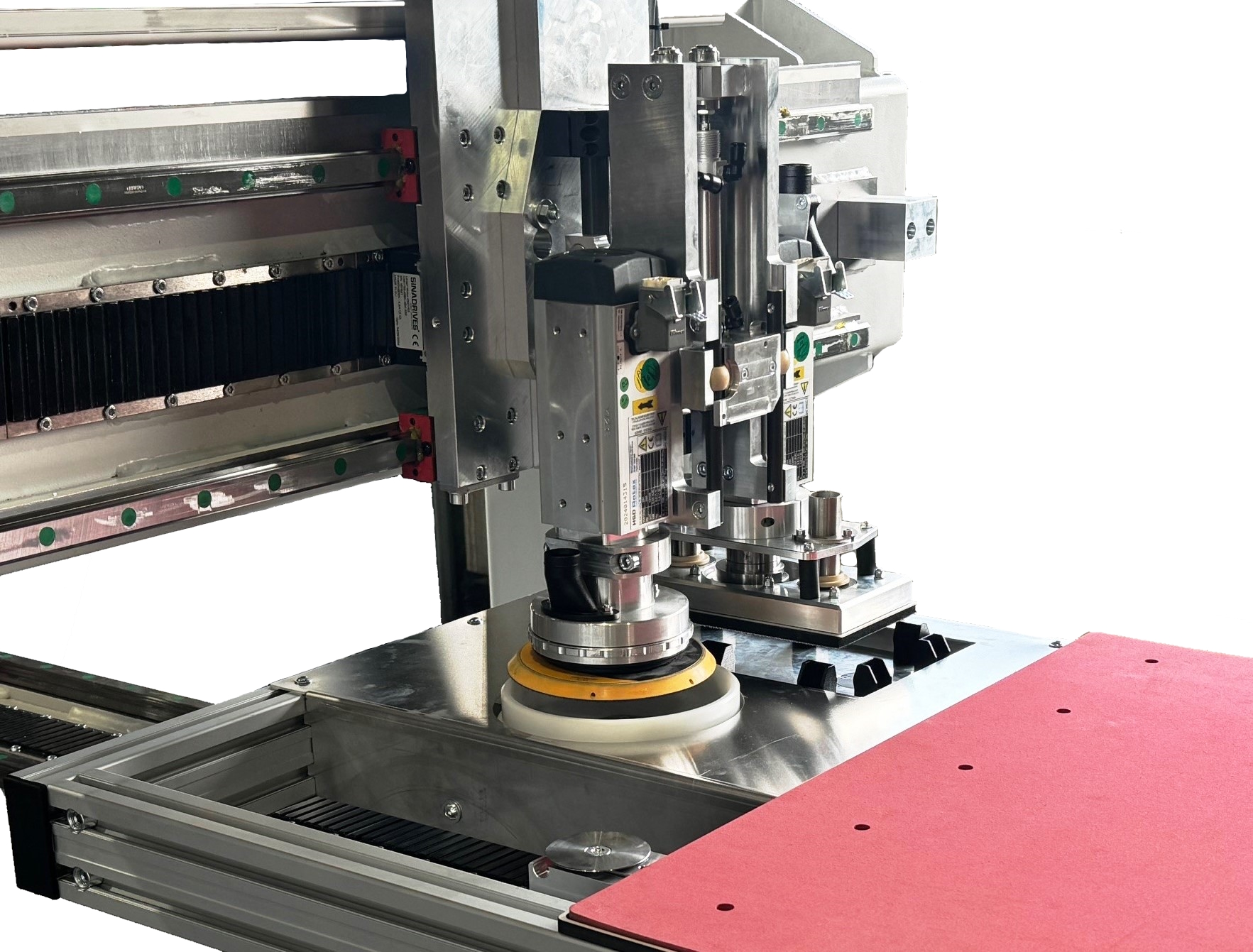

The ROBA Orbital is equipped with two sanding units, whereby the unit with the rectangular sanding pad is intended for the filling area and the unit with the round sanding pad for the frame rails or surfaces.

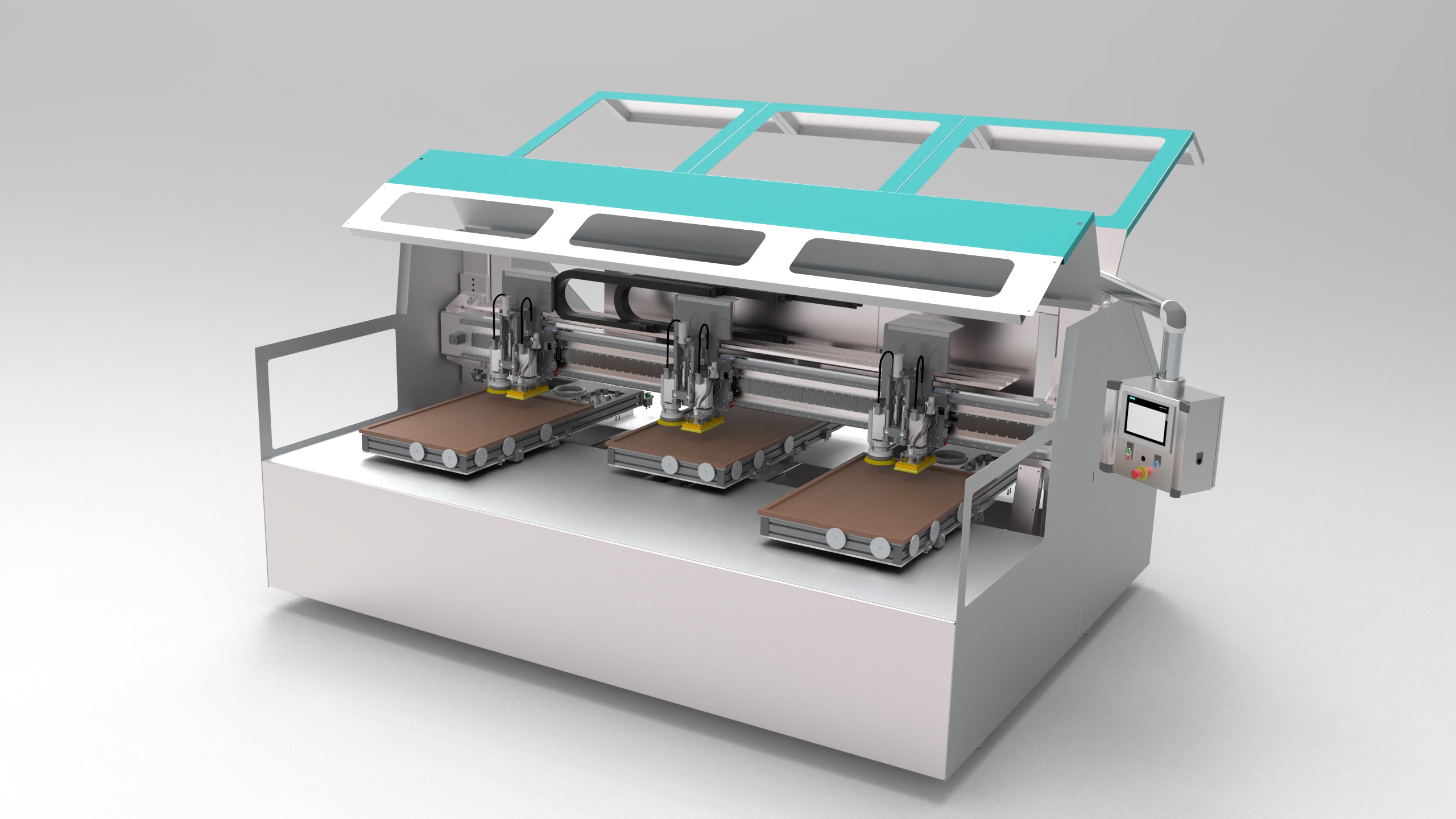

Three tables ensure a high capacity because they work independently of each other: one table is loaded, one table is processed, one table is emptied. This creates a constant, high-performance workflow in a safe and dust-free environment.

The workpiece and frame width measurement is carried out separately and automatically for each table, while the cabinet door is moved into the machining area.

Long parts, such as interior doors, are placed transversely on the three processing tables, which are electronically coupled in the Y direction, and processed simultaneously by the three orbital units.

Fresh sanding discs are provided automatically by a programmed sequence from the tool changer at the back of the worktable. This results in a constant sanding quality with high output.

MB has set up new service contacts for our customers:

German cell phone: 0049 151 4627 2124 – 7:00 bis 22:00 Uhr CET

US cell phone: 001 704 808 9171 – 6:00 am to 5:00 pm EST

SMS and WhatsApp available

service(at)mb-maschinenbau.de or service(at)mb-machinery.com (24/7)

weiterlesen…